CNC Metal Cutting

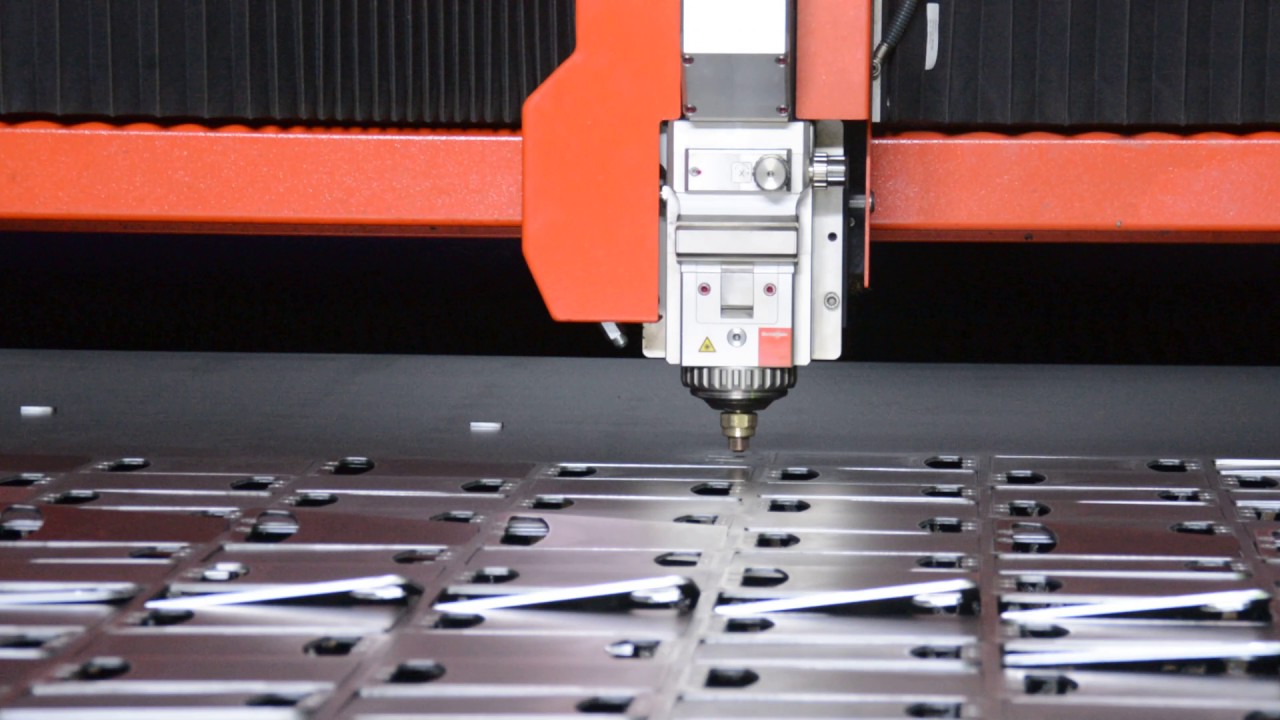

Programmable metal cutting machines remove the need for manual machine operators, which promotes accuracy, reduces human error, and increases process speed and efficiency.

Usages

- CNC laser cutting is used to achieve accurate shapes formation for small and large metals parts

- It is used to cut large sheets of metal into smaller partitions

- It is widely used in the in many industries such as automotive, medical, construction – where high precision and cutting efficiency is required

Our Capabilities:

Metaline operates large 12 KW fiber laser cutting machine, this machine is the first of its kind in Canada. This modern laser cutting machine has 0 gas emission, reduced energy consumption and 50% less waste generated during operation. We can accommodate metal sheet cutting up to 78 inches by 157 inches size.

Technical Specs

| Metal | Max Thickness in Inches |

| Aluminum | 1.125 |

| Brass | 0.625 |

| Copper | 0.625 |

| Galvanized Steel | 0.187 |

| Stainless Steel / Nirosta | 1.125 |

| HR (hot roll steel) | 1.125 |

- Sheet Size – 78” x 157”

- Cutting Tolerance – +/- .002”

Step 1 - Project Submission

Our engineers will work with you directly in order to fully understand your requirements as well as provide options regarding materials, finishes and other specifics. It’s our goal to establish a long-lasting relationship with all of our customers and we recognize that this initial step is crucial in setting the trajectory for the entire project.

Step 2 - Drawing Submission

We will take the submitted specification and prepare pre-production drawings/models/blueprints which we will submit to you for approval. Any changes that need to be performed can be done so at this stage and we’ll ensure that they are made in accordance with the original specifications.

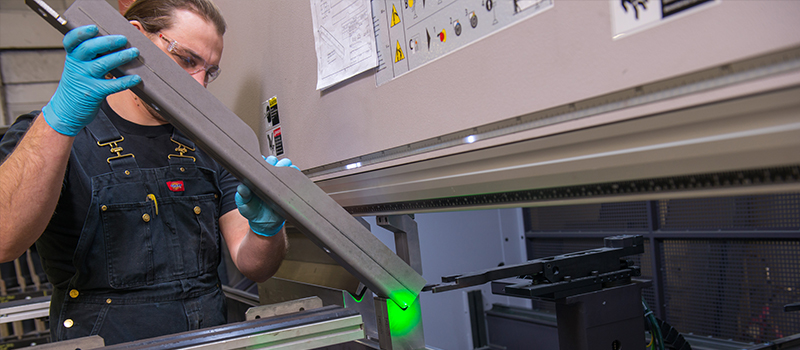

Step 3 - Fabrication

During this stage, we will fabricate your products based on the approved specification, guidelines and timeframes. You will always know exactly what stage your project is in.

Step 4 - Quality Control

Our QC team will inspect the finished materials for defects and ensure that the everything was completed to the original specifications.

Step 5 - Delivery

Optionally, we offer delivery services as well for projects of any size and can ship your fabricated materials via ground, sea or air to any major worldwide destination.

Laser Cutting

Laser cutting is one of the most efficient ways of cutting various metals with a high level of accuracy, and precision cut burr free parts. This will enable increased production times with a greater precision and accuracy, with minimal operator intervention. Our company continuously produces quality parts, at competitive pricing by maximizing productivity, without compromising quality.

Precision Cutting (Laser Fiber Cutting)

Laser cutting is a process which is used to cut sheets of metal with high-level of accuracy. The precision laser cuts through any metal like iron, copper, aluminum or stainless steel with ease. It is widely used in the automotive, aerospace and ceramics industries.

Plasma Cutter vs Laser Cutting

There are two main industrial cutting machines: CNC Plasma Cutter and CNC Laser Cutter.

The Plasma Cutter is used to cut different kinds of metals that lie in the medium thickness range. This machine uses the power of plasma to melt metal sheets in a certain area, but due to warping effect and metal deformation, the results are not always precise.

The Fiber Laser Cutter, modern and more advanced technology, can be used to cut all kinds of materials, including metals, with wide range of thickness and high. This makes laser cutting the go-to method for most of the metal sheet fabrication today.

Service Area:

Metaline shop is located in Toronto, at the heart of Canada’s largest business cluster, and minutes drive from YYZ – busiest Canadian airport. We serve customers from all industries in Ontario and across Canada. We also deliver orders and projects in the USA – we are easy to reach within less than 2 hours drive from New York state border.

No matter what size or complicity your CNC laser cutting project, we are here to assist you.

Contact us today via phone or email, share your requirements, and our engineers would be happy to provide detailed quote for your project.

FAQs

Laser cutting is a method that uses a laser to cut different types of metals into custom designs. The advantages of this technology are high precision and accuracy. Laser cutting is widely used in industries requiring accuracy, such as construction, medical and automotive. In addition, it is used by small businesses, DIYers and schools.

Laser cutting is suitable for projects that require high precision and can be used for thin metals. Waterjet uses high water pressure to cut through metal. Both of these methods can be used for cutting various materials. However, the water jet can be used for cutting thicker materials ranging from 0.4″ to 2.0″.

Plasma cutters use high-temperature gas to cut through metal, while a laser cutter uses a laser beam. A laser provides high precision and is quicker, but it costs more. However, plasma can be used for cutting thicker materials than lasers and is a cost-efficient cutting method.

A laser cutter can be used for various metals, such as non-ferrous metals, mild steel, and stainless steel. The cutting process is very accurate and is perfect for detailed designs. The laser is suitable for cutting through thin metal.

Laser cutting is one of the methods used for cutting sheet metal, coming with a wide range of advantages. Laser cutting is cheaper when compared to other cutting methods. The process includes automation, so the costs for labor are low. In addition, a laser is durable and enhances productivity with the simple process.

- Cost efficiency. Laser cutting comes with lower costs, as the need or labor is reduced due to automation.

- Speedy process. Laser cutting moves with a speed of 20 to 70 inches per minute.

- High precision. Laser is an excellent choice for detailed cuts with smooth edges and precise curves.