Carbon Steel Fabrication

We have a large inventory of Carbon Plate products that range from 3/16” to 1.000” in thickness and different grades that includes mild steel, 50 W, 44 W, and AR 500 and Armour plate.

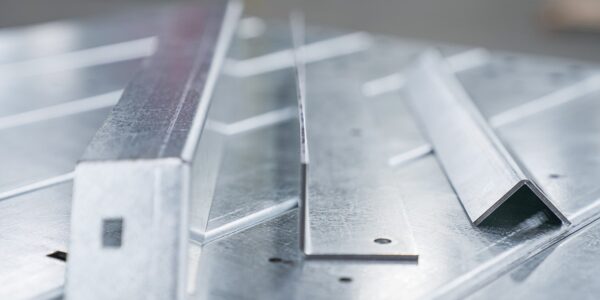

View Service DetailAluminum Fabrication

Aluminum offers excellent corrosion resistance properties which is a beneficial feature and the addition of pre-painted or anodized finishes provide extreme durability indoors as well as outdoors.

View Service DetailStainless Steel Fabrication

We at Metaline manufacture an extensive range of stainless steel products with a comprehensive range of fittings, welding consumable, and flanges. All the stainless products are available in different grades, surface finished and dimensions.

View Service DetailGalvanized Steel Fabrication

Metaline offers a comprehensive range of galvanized sheets to domestic as well as international markets. Galvanized sheets are available in a variety of width, length and thickness and different dimension that fit the requirements of the customers.

View Service DetailCold Rolled Steel Fabrication

At Metaline we offer cold rolled sheets that are used in different applications like an exposed painted part or application which has tight tolerance on gauge restrictions.

View Service DetailHot Rolled Pickled & Oiled Steel Fabrication

At our company we offer different types of gauges, size, and grades of hot rolled / picked and oiled sheets that will meet all your metal fabrication needs.

View Service DetailMetaline produces high quality fabricated metal items to clients for quite a few years. The assortment of fabricated metal elements we make depends on the requirements of our customers. This way we are capable of remaining connected with multiple industries and maintain diversity.

We offer metal fabrication service by using top grade technology. With new technology we try to evaluate and attain equipment which will complement the present equipment and assist in streamlining the workflow. The result will speak for itself as customers can get quality products. From carbon plate products to a variety of hot rolled/pickled and oiled sheets that will suit all your requirements.

Customers can also get cold rolled sheets at Metaline which are used in different applications. You can also get galvanized steel which are used for different applications and the main reason for using it is for preventing corrosion. Stainless steel products are available in different shapes like plate and sheet. It is produced with low carbon content that makes it an ideal corrosion resistant product. Customers can also get aluminum that comes with various properties which is used extensively in various applications.

The fabricated metal products that we supply are utilized throughout numerous industries. We understand the strategic growth and train our staff for metal fabrication so that we are capable of manufacturing fabricated metal products for many more years in the future. At our company we focus on handling all fabricated metal parts in the most flawless and professional way possible. This offers the customers the liberty to concentrate on the core competencies and focusing on growth.

Metal Fabrication FAQs

The metal fabrication process involves shaping raw metals and semi-finished metal products into a specific form, such as a machinery part, metal structure or finished product.

The process includes bending, forming, cutting, burning, welding, machining, and assembly of the final product.

There are many different fabrication methods. The most popular methods include:

- Forging

- Casting

- Forming

- Machining

- Extrusion

- Cutting

- Punching

- Stamping

- Welding

- Drilling

- Bending

- Shearing

Since in most of the cases the metals enter the fabrication stage as semi-finished or pre-fabricated products as rolls, plates or sheets, the most common techniques are:

- Cutting: Cutting parts of raw metal using torches, water jets, lasers or plasma CNC cutting machines.

- Bending: Forming the metal sections and pieces into the required shape by bending it using brake press machinery.

- Assembling: The final stage of most metal fabrication processes is assembling metal parts or sheets into the product’s final form. This can be done by welding, seaming, screwing and fastening parts together.

Metal fabrication machines include:

- Lathe Machines

- CNC Laser Cutting

- Milling Machine

- Powder Coating Rooms

- Grinding Machine

- CNC Routers

- Drilling Machines

- Shaper Machines

- Broaching Machines

- Saw Machines

- Planer Machine

- Shearing Machines

- Drill Press

- Brake Press

Metal fabrication tools include:

- Cutting Saws

- Deburring Tools

- Beveling Tools

- Grinders

- Throatless Shear

- Wire Cutters

- Drill Bits

- An Auto-darkening Helmet

- Angle Finders

- Cutting Glasses

- Drill Bits

For most metal fabrication services such as welding, cutting and press-bending, both the fabrication shop and each fabricator have to be separately certified.

Product design is the general idea of a product’s functionality, characteristics and uses; it could simply be a concept designed by a designer, inventor or any individual.

Fabrication design (or production design) is the planning of the actual manufacturing, be it a prototype, finished product or production line to produce it. This would typically be designed by engineers or CNC programmers.

Welding is one of the fabrication stages of metal fabrication, whereas metal fabrication is the overall process.

Steel Fabrication FAQs

Steel fabrication is a process of shaping, forming and combining structures out of steel and its alloys. Steel fabrication includes cutting, bending and assembling metal components into the desired end product or prototype according to an engineer’s specifications.

The steel fabrication process includes (but is not limited to) cutting, machining, punching, drilling, bending or straightening, rolling, welding, forming and final component assembly.

Carbon Steel – A type of steel containing carbon element on a 0.05% to 2.1% percent scale. This type of steel becomes stronger after heat treatment, but loses its flexibility. It’s also harder to fabricate.

Stainless Steel – This is a steel alloy of iron, chromium and other metals such as nickel. The corrosion-resistance properties make it widely used across industries like food, medicine, energy and construction.

Galvanized Steel – This is a steel with a protective zinc coating layer applied to protect it from corrosion.

Aluminum – This is a steel alloy with special properties of lightness, flexibility and corrosion-resistance, which is used in many industries such as aviation, aerospace, automotive, and medical.

Custom fabrication is a full cycle metal fabrication process conducted by the manufacturer – including fabrication engineering, prototype design, production, assembly, and delivery logistics of the final product to the client’s facility.

Fabrication shops, or fabricators, conduct the processes of shaping raw metal components into parts that used to build final products such as machinery or metal structures across different industries. Fabricators work according to the specifications provided or engineer custom prototypes based on their client’s ideas.

Stainless steel has almost the same properties as regular steel, except it has more flexibility which makes its fabrication relatively easy. However, engineering such as strengthening and hardening is more complex and only offered by specialized fabrication shops.

Typically, a steel fabrication engineer is responsible for designing a steel product, commissioning the manufacturing process, and in many cases, setting up the specifications and functions of the entire manufacturing line.

Each process or end product is calculated individually based on the level of customization, fabrication complexity and other production components. As a basic calculation, the costs of steel fabrication could be estimated as about 3 times that of the initial raw material. So if the cost of the raw metal itself is $500, its fabrication into structural steel could cost around $1500.