Aluminum Fabrication

Aluminum is usually available in 3 grade specifications, 6000 series, 5000 series and 3000 series. The 3000 series is a commercial quality product for general purpose applications, whereas the 5000 series is used for architectural and decorative applications which could require an anodized finish. This series has great corrosion resistance, formability and weldability, which make it popular in tanks, pressure vessels and also the marine industry. The 6000 series has excellent mechanical properties and weldability which is used extensively in different structural applications. At Metaline we have the expertise and equipment for all of your aluminum fabrication requirements.

Why Choose Us

Our professionals are well experienced and trained to handle the metal fabrication jobs. We have the best machineries to meet the requirements of our customers and satisfy them completely. Customer satisfaction and production of flawless products is our prime goal and our engineers and professionals strive to achieve the same. At Metaline you will certainly have all your requirements met which will be beneficial for the growth of your business.

Step 1 - Project Submission

Our engineers will work with you directly in order to fully understand your requirements as well as provide options regarding materials, finishes and other specifics. It’s our goal to establish a long-lasting relationship with all of our customers and we recognize that this initial step is crucial in setting the trajectory for the entire project.

Step 2 - Drawing Submission

We will take the submitted specification and prepare pre-production drawings/models/blueprints which we will submit to you for approval. Any changes that need to be performed can be done so at this stage and we’ll ensure that they are made in accordance with the original specifications.

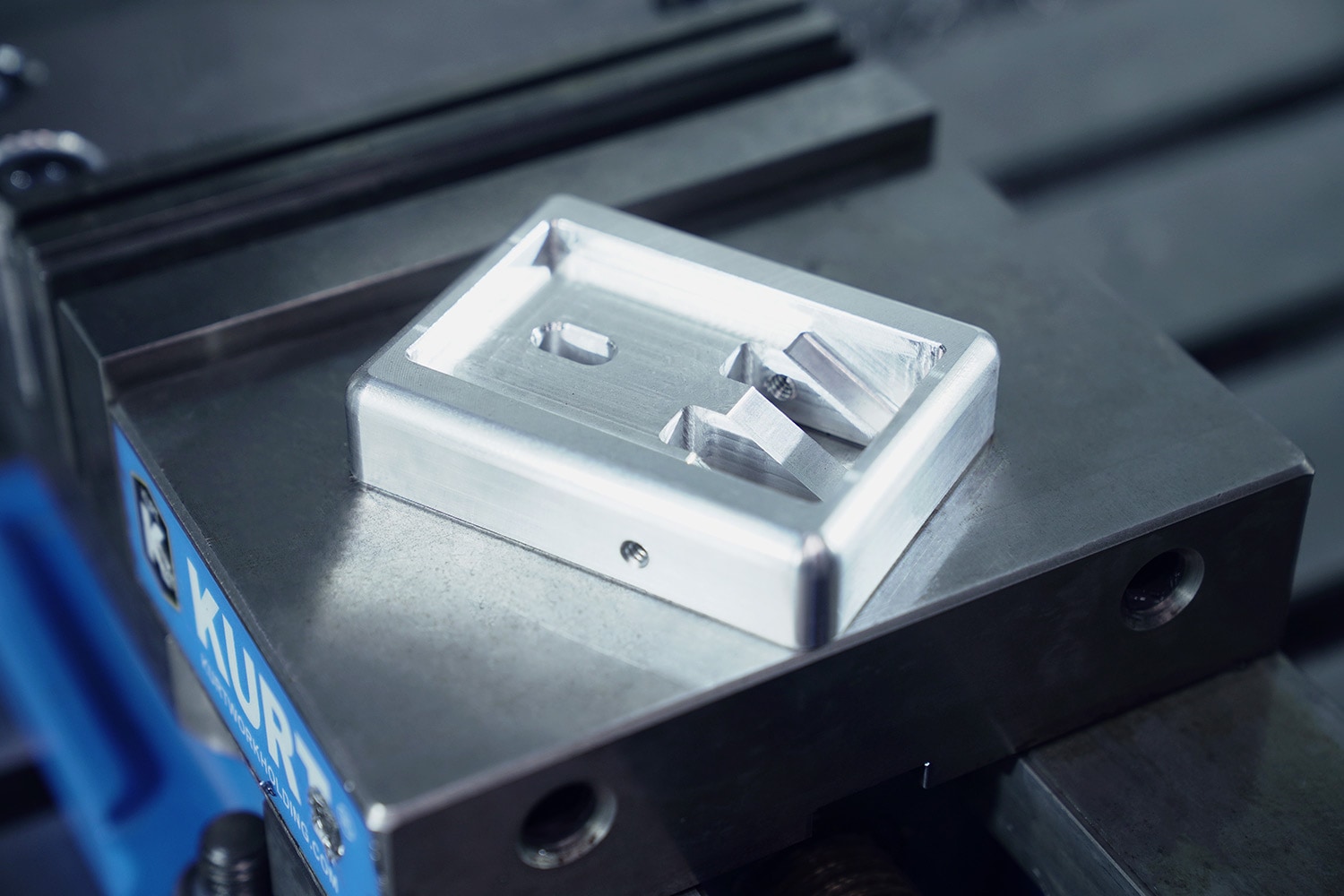

Step 3 - Fabrication

During this stage, we will fabricate your products based on the approved specification, guidelines and timeframes. You will always know exactly what stage your project is in.

Step 4 - Quality Control

Our QC team will inspect the finished materials for defects and ensure that the everything was completed to the original specifications.

Step 5 - Delivery

Optionally, we offer delivery services as well for projects of any size and can ship your fabricated materials via ground, sea or air to any major worldwide destination.

General Information on Aluminum

Aluminum is a low density non-ferrous material which finds use in a number of commercial applications. This material can be strengthened by adding special alloy elements and is used in both cast and wrought forms. It finds applications in different structural areas like fasteners, aircraft structures, curtain wall, architectural and many other applications.

Aluminum offers excellent corrosion resistance properties which is a beneficial feature and the addition of pre-painted or anodized finishes provide extreme durability in indoors as well as outdoors.

Service Area Coverage

Metaline shop is located in Toronto, at the heart of Canada’s largest business cluster, and minutes drive from YYZ – busiest Canadian airport. We serve customers from all industries in Ontario and across Canada. We also deliver orders and projects in the USA – we are easy to reach within less than 2 hours drive from New York state border.

No matter what size or complicity your aluminum fabrication project, we are here to assist you.

Contact us today via phone or email, share your requirements, and our engineers would be happy to provide detailed quote for your project.

FAQs

An aluminum fabricator is a fabrication shop that offers aluminum forming, cutting, bending and welding.

Additionally, it can be a metal fabrication expert who specializes in the above fabrication processes with aluminum and its alloys.

There are a few metal fabrication methods that provide the best results for aluminum, which include:

- Water-jet cutting

- MIG & TIG

- Adhesive bonding

- Extrusions

- Drawing

- Forming

- Casting

- Forging

- Press-bending

Aluminum’s unique properties, which include its softness compared to other metals, makes it is easy to work with, shape, and fabricate. Also, aluminum is usually supplied as a semi-finished product – such as metal sheets that are ready for forming.

Due to its properties of easy formation, lightness and water resistance, aluminum is used in a variety of industries such as food preservations, kitchen utilities, construction, automotive, marine machinery and even aerospace.