Hot Rolled Pickled & Oiled

At Metaline we offer different types of gauges, size, and grades of hot rolled / picked and oiled sheets that will meet all your metal fabrication needs. Some usual grades that are offered by us are high strength low-alloy, commercial quality and HSLA formable. These are found in different widths, lengths and gauges. Whether you need semi-finished, full sheets or finished fabricated parts from 0.050” – 0. 179” thickness, we have the capability for supplying all your requirements.

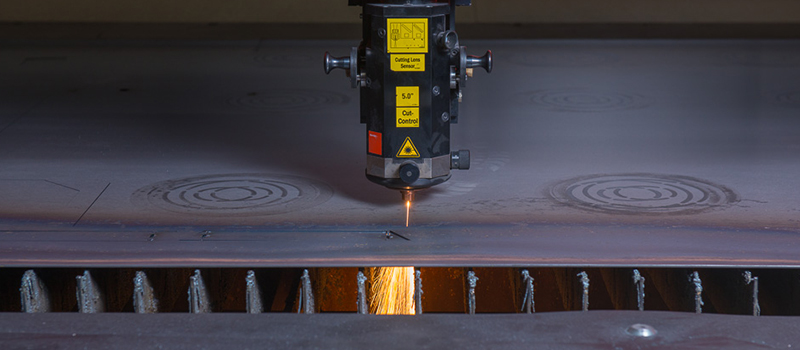

HRPO Steel Fabrication

Pickled and oiled steel fabrication (HRPO) is a chemical process that removes impurities such as stains, rust, scale and other surface impurities and then coated with a thin layer of oil to protect it from oxidization. Hot Rolled Pickled and Oiled Sheets are primarily used in end use applications that are exposed and or painted parts or metal stamping applications.

Looking for a HRPO fabricator in Canada? Feel free to request a quote.

Contact us today via phone or email, share your requirements, and our engineers would be happy to provide detailed quote for your project.

Why Choose Us

Our professionals are well experienced and trained to handle the metal fabrication jobs. Our machinery and processes are aligned with 44/50W ASTN standard. At Metaline you will certainly have all your requirements met which will be beneficial for the growth of your business.

Service Area Coverage

Metaline shop is located in Toronto, at the heart of Canada’s largest business cluster, and minutes drive from YYZ – busiest Canadian airport. We serve customers from all industries in Ontario and across Canada. We also deliver orders and projects in the USA – we are easy to reach within less than 2 hours drive from New York state border.

HRPO Project Submission - Step 1

Our engineers will work with you directly in order to fully understand your requirements as well as provide options regarding materials, finishes and other specifics. It’s our goal to establish a long-lasting relationship with all of our customers and we recognize that this initial step is crucial in setting the trajectory for the entire project.

Step 2 - Drawing Submission

We will take the submitted specification and prepare pre-production drawings/models/blueprints which we will submit to you for approval. Any changes that need to be performed can be done so at this stage and we’ll ensure that they are made in accordance with the original specifications.

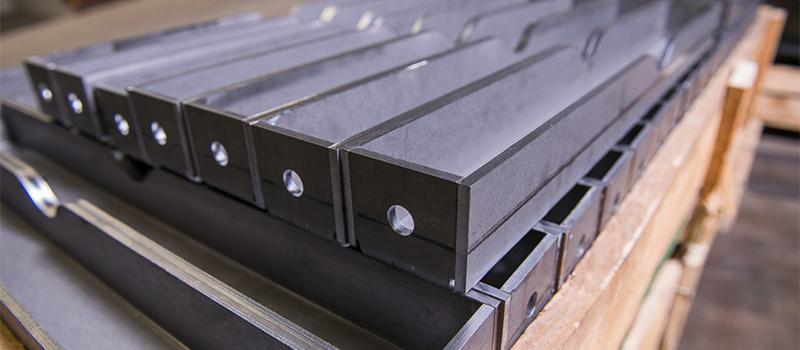

Step 3 - Fabrication

During this stage, we will fabricate your products based on the approved specification, guidelines and timeframes. You will always know exactly what stage your project is in.

Step 4 - Quality Control

Our QC team will inspect the finished materials for defects and ensure that the everything was completed to the original specifications.

Step 5 - Delivery

Optionally, we offer delivery services as well for projects of any size and can ship your fabricated materials via ground, sea or air to any major worldwide destination.