Technical Specs

High speed vertical machining centre, with 5-axis, for milling operations on variety of materials and sizes up-to 6 x 4 x 1.5 meters. Range of materials include: Alloys, Aluminum and composites including foam, plastic, carbon fiber and more.

5-Axis CNC Capabilities

The ideal solution for machining medium and large size workpieces and perfect for creating models, for contouring plastic, composites, sandwich materials as well as for machining complex workpieces in light alloys used across a number of applications in the aerospace, model making and die manufacturing industries.

Step 1 - Project Submission

Our engineers will work with you directly in order to fully understand your requirements as well as provide options regarding materials, finishes and other specifics. It’s our goal to establish a long-lasting relationship with all of our customers and we recognize that this initial step is crucial in setting the trajectory for the entire project.

Step 2 - Drawing Submission

We will take the submitted specification and prepare pre-production drawings/models/blueprints which we will submit to you for approval. Any changes that need to be performed can be done so at this stage and we’ll ensure that they are made in accordance with the original specifications.

Step 3 - Fabrication

During this stage, we will fabricate your products based on the approved specification, guidelines and timeframes. You will always know exactly what stage your project is in.

Step 4 - Quality Control

Our QC team will inspect the finished materials for defects and ensure that the everything was completed to the original specifications.

Step 5 - Delivery

Optionally, we offer delivery services as well for projects of any size and can ship your fabricated materials via ground, sea or air to any major worldwide destination.

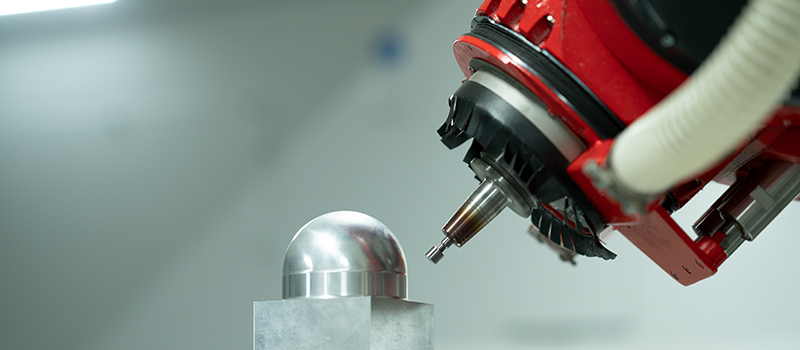

CNC 5-Axis Machining

The High-speed 5-axis machining centre is made for milling, boring and trimming small to large size work-pieces in composite materials, sandwich structures, light alloys, resin and plastic. This will enable decreased production times with a greater precision and accuracy, with minimal need for operator intervention. The end result is that our company will continuously produce quality parts, at competitive pricing by maximizing productivity, without compromising quality.

Did you know?

Metaline has recently purchased and installed a Breton Eagle 5-Axis CNC Machine at our Toronto facility. The machine features a new range of high-speed 5-axes CNC milling machining centers with a gantry design and highly-dynamic mobile crossbeam specifically designed and developed for machining composite materials, resin, light alloys and the ideal solution for high-speed production requirements and for precision 5-axis milling operations on the five faces of the workpiece in just one setup.

Request an Estimate

No matter what size or complicity your CNC machining project, we are here to assist you. Contact us today via phone or email, share your requirements, and our engineers would be happy to provide detailed quote for your project.

FAQs

An advanced computer numerical controlled (CNC) process of simultaneously moving cutting tools along 5 axes. This technology enables machining of complex parts and prototypes quickly and with exacting precision.

Some of the key advantages include:

- Ability to mill and machine highly complex shapes with more precision

- Faster setup and machine programming

- Higher accuracy and better parts surface finishing

- Increased tool lifecycles due to automatically adjusting the work surface to the ideal cutting position

Computer numerical control (CNC) fabricating enables the machine to be programmed for the highest degree of accuracy so that it can meet exact specifications and geometrically match other parts.

Accurate and precise CNC fabrication can be achieved with 5-axis machining, even for the most complex shapes.

The main difference is the number of axes a workpiece can be rotated to and worked on from.

The more axes a CNC machine has, the more complex its movement becomes in adjusting the position of the workpiece and the cutting tools. The more complex the motion, the more advanced and precise the geometry of the final machined shape can be.

All standard materials can be fabricated by a 5-axis CNC machine with the proper speed, nozzle and feed settings, but the most common materials are:

- Metals: aluminum, brass or steel

- Plastics: such as POM, PMMA, PC and PP

- Wood: hardwood, plywood or softwood

- Foam: such as carving foam and rigid foam

Computer numerical control (CNC) machining is used in many industries such as construction, manufacturing, automotive, marine and more. It is also required in industries with strict standards such as electronics, aviation, aerospace and the medical industry.

This is a process where the CNC machine is used to create a prototype. Prototype machining has many advantages:

- Leverages CNC programmed equipment for the most precise result

- Delivers the fastest turnaround for prototyping

- Machines any materials including hard metals

5-axis machining can process and mill a workpiece from multiple directions simultaneously, with high accuracy.

This allows for the manufacturing of complex parts and shapes, with unmatched quality – from simple automotive details to aerospace parts requiring exacting precision.

The 5-axis process is compatible with any standard and non-standard materials, thus is has virtually zero limitations.