What is CNC Milling?

A CNC Milling machine uses a cutting tool, usually one that rotates to make holes or cut through a material with incredible precision. A particular design or pattern is programmed into the system and the machine goes to work immediately to carve out unique custom-designs. Most workshops use 3 axis or 5 axis milling machine for complex projects. However, 5 axis machines are more expensive and found in less CNC milling shop (Metaline operates 5 axis machine). 5 axis CNC provides more agile and accurate result, as well as faster delivery of required result.

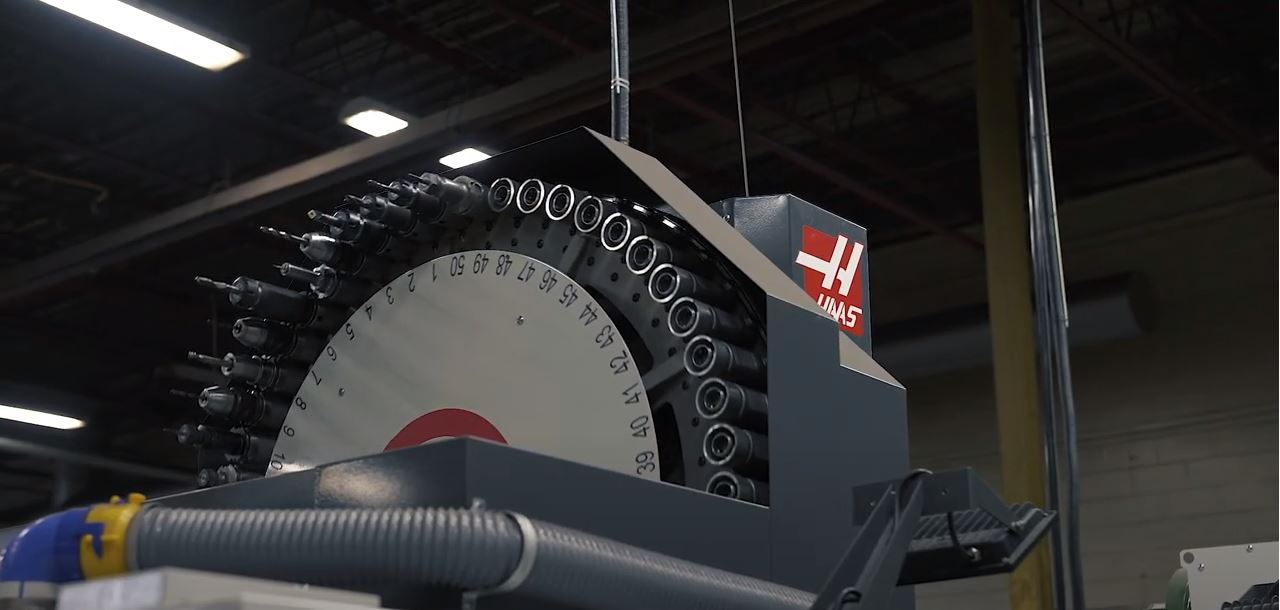

Our Capabilities

We operate 2 CNC Milling machines:

- VF5-SS 3 Axis

- Braton Eagle 5 Axis

Step 1 - Project Submission

Our engineers will work with you directly in order to fully understand your CNC lathe job requirements as well as provide options regarding materials, finishes and other specifics. It’s our goal to establish a long-lasting relationship with all of our customers and we recognize that this initial step is crucial in setting the trajectory for the entire project.

Step 2 - Drawing Submission

We will take the submitted specification and prepare pre-production drawings/models/blueprints which we will submit to you for approval. Any changes that need to be performed can be done so at this stage and we’ll ensure that they are made in accordance with the original specifications.

Step 3 - Fabrication

During this stage, we will fabricate your products based on the approved specification, guidelines and timeframes. You will always know exactly what stage your project is in.

Step 4 - Quality Control

Our QC team will inspect the finished materials for defects and ensure that the everything was completed to the original specifications.

Step 5 - Delivery

Optionally, we offer delivery services as well for projects of any size and can ship your fabricated materials via ground, sea or air to any major worldwide destination.

Service Area Coverage

Metaline shop is located in Toronto, at the heart of Canada’s largest business cluster, and minutes drive from YYZ – busiest Canadian airport. We serve customers from all industries in Ontario and across Canada. We also deliver orders and projects in the USA – we are easy to reach within less than 2 hours drive from New York state border.

Process Description

The workpiece is held in place using a set of clamps. Once the material is secured in its place, the CNC milling machine begins its work by cutting, shaping and removing pieces of the material to match it with the pre-programmed design. This process is predominantly used on metals, such as steel, copper, aluminum and other alloys. Such milling process is fast and accurate, leaving no chance of errors after programmed and tested on prototype parts.

Usages:

- Used to drill, bore or cut flat pieces of metal

- It also helps shape non-flat surfaces

- CNC Milling is used to create metal objects with patterns and complex structure

- It is also used for designing prototypes and 3D models

No matter what size or complicity your CNC milling project, we are here to assist you. Contact us today via phone or email, share your requirements, and our engineers would be happy to provide detailed quote for your project.

FAQs

CNC milling is the computer numerical controlled (CNC) process of removing material from the surface of a workpiece and forming it into the desired part. It uses rotating multi-point cutting machinery to accurately achieve the specifications for the final product.

CNC milling is used to shape parts and structures to meet the precise specification of their design, thus it’s used across almost all industries, from automotive to aerospace and military.

Virtually any material can be milled with the proper machinery and tooling. But the most common materials are wood and plastic as well as aluminum – due to its machinability, workability and versatility.

CNC milling machines can be used to produce virtually any design or shape – including prototypes, sculptures, parts of structure, and more. It can be used on a variety of materials such as wood or PVC, metal alloys, plastics and polyurethanes.

Machining tolerance, or dimensional accuracy, is the amount of permitted variance in a part’s dimensions. Standard tolerance for a CNC machining service is typically ± 0.005”. The tightest machining tolerances possible are in the range of ±0.001” – roughly the width of a human hair.

Although super-accurate milling machines exist, such as micro-precision machines with 0.00007″ tolerance, most of the milling machines are built for a tolerance (accuracy) ranging from ±0.02” (±0.00508 mm) to ±0.0005” (±0.0127 mm).

In machine tools, a spindle is a rotating axis of the machine, which often has a shaft at its core. Its purpose is to hold the tool – whether it be a milling, cutting or drilling nozzle.

Fabrication shops usually build their quotes as work hour estimates: 3-axis milling machine usage generally starts from $80 per hour, and 5-axis machine usage can be anywhere between $110 to $150 per hour or higher. These costs also include human labor.