Canadian Stainless Steel Fabricator

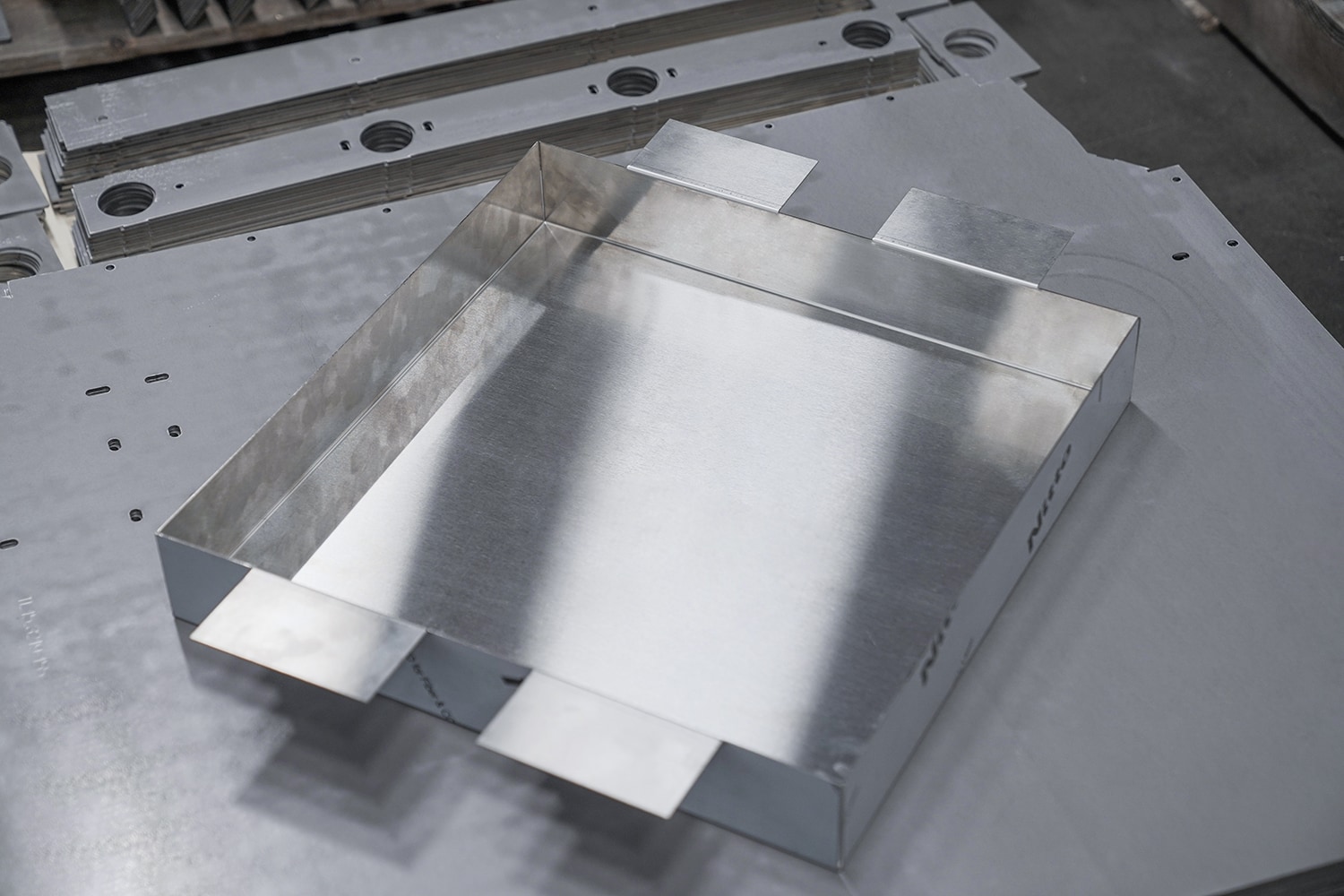

We at Metaline manufacture an extensive range of stainless steel products with a comprehensive range of fittings, welding consumable, structural steel fabrication and flanges. All the stainless products are available in different grades, surface finishes and dimensions. Precision metal fabrication is achieved by using latest CNC laser cutting technologies – we upgrade our machinery on annual basis and keeping up with the latest industry technology.

Grades and Type of Stainless Steel We Offer:

- 409 Stainless

- 304 Stainless

- 316/316L Stainless

Available Finishes:

- 2B or mill finish

- #4 or brushed finish

- #8 or mirrored finish

Why Choose Us

Our professionals are well experienced and trained to handle the metal fabrication jobs. We have the best machineries to meet the requirements of our customers and satisfy them completely. Customer satisfaction and production of flawless products is our prime goal and our engineers and professionals strive to achieve the same. At Metaline you will certainly have all your requirements met which will be beneficial for the growth of your business.

Project Submission - Step 1

Our engineers will work with you directly in order to fully understand your requirements as well as provide options regarding materials, finishes and other specifics. It’s our goal to establish a long-lasting relationship with all of our customers and we recognize that this initial step is crucial in setting the trajectory for the entire project.

Step 2 - Drawing Submission

We will take the submitted specification and prepare pre-production drawings/models/blueprints which we will submit to you for approval. Any changes that need to be performed can be done so at this stage and we’ll ensure that they are made in accordance with the original specifications.

Step 3 - Fabrication

During this stage, we will fabricate your products based on the approved specification, guidelines and timeframes. You will always know exactly what stage your project is in.

Step 4 - Quality Control

Our QC team will inspect the finished materials for defects and ensure that the everything was completed to the original specifications.

Step 5 - Delivery

Optionally, we offer delivery services as well for projects of any size and can ship your fabricated materials via ground, sea or air to any major worldwide destination.

About Stainless Steel Usages

Stainless steel products are increasingly the material of choice for metal fabrication. We supply stainless steel products that are available in a wide variety of dimensions and grades and our metal fabricators are well trained and provide flawless stainless steel fabricated products. Our company will assist you in meeting all your stainless steel requirements.

Stainless Steel products are available in plate, sheet, and various other shapes. This can be bought as a Mill finish or can be polished to bright mirror finish depending on the application. The steel is manufactured with a low carbon content that makes it an ideal corrosion resistant product.

The two main types of stainless steel usually used are the 400 series and 300 series. The 300 series is mainly used in different applications like marine aerospace and any other areas which is directly exposed to different elements throughout the year. The 400 series stainless steel has properties which are corrosion resistant and is mainly ideal for interior decorative, architectural and appliances.

Service Area Coverage

Metaline shop is located in Toronto, at the heart of Canada’s largest business cluster, and minutes drive from YYZ – busiest Canadian airport. We serve customers from all industries in Ontario and across Canada. We also deliver orders and projects in the USA – we are easy to reach within less than 2 hours drive from New York state border.

Do not hesitate to contact us by phone or email and share your stainless steel fabrication project requirements with Metaline dedicated team of experts.

FAQs

Stainless steel is an alloy of chromium and iron, known for being highly resistant to corrosion and heat. It must contain 10.5% of chromium to be considered stainless steel, but other metals can be added to enhance the properties of this alloy. Its appealing look and durability make stainless steel a popular choice for various industries.

- Austenitic stainless steel contains high levels of chromium. The alloy is corrosion-resistant and durable.

- Ferritic stainless steel contains low levels of nickel and low carbon consistency and has magnetic properties. Some of its advantages are cost-effectiveness and durability.

- Duplex stainless steel combines ferritic and austenitic, featuring enhanced durability.

- Martensitic stainless steel comes with higher carbon content and is less commonly used when compared to the other types. In some industries, it gets a protective coating layer to prevent corrosion.

Stainless steel is an alloy that contains a minimum of 10.5% of chromium. On the other hand, galvanized steel is steel with a zinc coating to make it corrosion-resistant. However, the protective zinc layer can wear off. Stainless steel is stronger and more resistant to rust but is more expensive than galvanized steel.

Stainless steel makes its way into many industries:

- Construction. Stainless steel is used in cladding but can be used in interiors as a decorative finish. It can be easily welded, has an attractive look, and is corrosion-resistant.

- Transportation. The use of this alloy is favored in creating car parts, road tankers, ship containers, buses, trucks, railway cars, and aircraft.

- Medical. Since stainless steel is prone to corrosion, you can easily sterilize it for medical purposes.

- Energy industry. Stainless steel is resistant to toxic substances and is used for producing tanks, pipes, and valves.

- Food. The easy cleaning process makes this alloy ideal for kitchen accessories and appliances.

Fabrication of stainless steel refers to creating a final product or a component that will be used in construction and assembly. The alloy is quite malleable and elastic, so the process includes various techniques such as cutting, burning, bending, forming, welding, and assembling.

Stainless steel can be challenging to work with. However, having the right equipment will help. The different types of stainless styles come with different workability. It can be cut with the standard methods such as laser, plasma, waterjet, hand sawing, abrasive disc cutting, etc.

Compared to other metals such as aluminum, stainless steel is difficult to work with. The sturdiness of steel will generate heat when machining, which will result in decreased tool lifespan. Therefore, machining stainless steel requires complex methods that end up costing more.

Stainless steel won’t weaken when bent cold. Due to its sturdiness, steel is known to be difficult to bend. Carbon steel is an ideal choice for bending since it is flexible.

- Laser cutting is the best method for cutting stainless steel. The result is clean and precise lines that you can’t replicate with any other method.

- Plasma is suitable for thicker pieces of stainless steel and is cost-efficient. However, it doesn’t come with clean lines.

- Waterjet is commonly used to cut stainless steel and doesn’t require finishing.

- Saw cutting results in a clean-cut but has limits regarding the steel thickness

Yes, stainless steel can be milled. It comes in four types with different machinability: austenitic, ferritic, duplex, and martensitic. Therefore, the method used will depend on the type you work with.