Our Capabilities

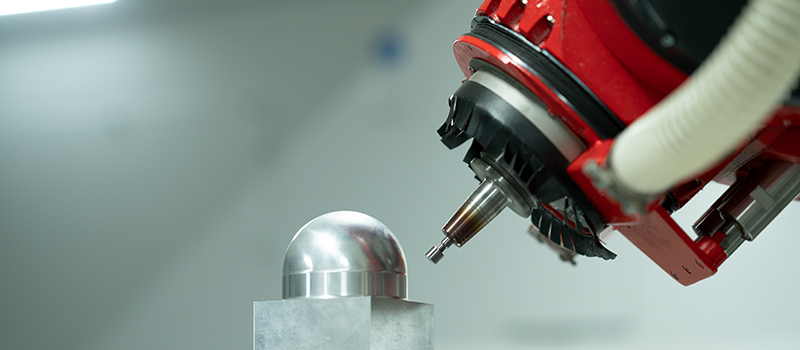

We operate INFINITE CNC Router machine equipped with 3-axis laser heads.

Service Area Coverage

Metaline shop is located in Toronto, at the heart of Canada’s largest business cluster, and minutes drive from YYZ – busiest Canadian airport. We serve customers from all industries in Ontario and across Canada. We also deliver orders and projects in the USA – we are easy to reach within less than 2 hours drive from New York state border.

Step 1 - Project Submission

Our engineers will work with you directly in order to fully understand your CNC router job requirements as well as provide options regarding materials, finishes and other specifics. It’s our goal to establish a long-lasting relationship with all of our customers and we recognize that this initial step is crucial in setting the trajectory for the entire project.

Step 2 - Drawing Submission

We will take the submitted specification and prepare pre-production drawings/models/blueprints which we will submit to you for approval. Any changes that need to be performed can be done so at this stage and we’ll ensure that they are made in accordance with the original specifications.

Step 3 - Fabrication

During this stage, we will fabricate your products based on the approved specification, guidelines and timeframes. You will always know exactly what stage your project is in.

Step 4 - Quality Control

Our QC team will inspect the finished materials for defects and ensure that the everything was completed to the original specifications.

Step 5 - Delivery

Optionally, we offer delivery services as well for projects of any size and can ship your fabricated materials via ground, sea or air to any major worldwide destination.

What is CNC Router?

A CNC routers are commonly found in the woodworking, furniture, and metalwork industries. CNC Router is a precision cutting tool that can cut and carve any shape into a metal sheet with unwavering accuracy. The design is programmed into the machine, which performs the process in a time-efficient and precise way.

Usages:

- It is used to carve and shape metal, wood or polyurethanes and other composite materials

- CNC routers are used for accurate results and repeating shapes production

No matter what size or complicity your CNC router requirments, we are here to assist you. Contact us today via phone or email, share your requirements, and our engineers would be happy to provide detailed quote for your project.

FAQs

A CNC router is a cutting machine used for cutting various materials, guided by a computer. The machine relies on an automatic process to create custom designs with high precision. The system will monitor and control the movements of a cutting machine, which is more accurate when compared to manual cutting.

A CNC routing machine is used for cutting through various materials, an efficient alternative to the handheld process. This method can produce very detailed shapes and finds implementation within many industries and can be used for aluminum, copper, and brass.

- High precision. A computer system controls the CNC router, which can entirely avoid human error.

- Simple process. The employees will have training for using these machines, and the risks of injury are minimized.

- Cost efficiency. The automated system will cost less due to the reduced labor costs. A small team will be needed for programming the software.

Depth per pass determines how deeply the machine will cut into the metal for each pass. The cutting process is divided into a few passes for a safer operational process and prolongs the machine’s lifespan. Each pass has a limit on how deep it can go, so you will need to cut thicker metals with a few passes.

The spindle speed ranges from 7,000rpm to 24,000rpm. The spindle speed refers to the rotational speed of the tool expressed in revolutions per minute.

CNC router is an efficient cutting method for the following metals:

- Aluminum

- Stainless steel

- Steel

- Titanium

- Copper

- Brass

- Magnesium